-

March 19th, 2015, 11:41 AM

#1

Senior Member

- Rep Power

- 10

A suitcase filled with old German fountain pens: An exiting project! PART 2 of 4

A suitcase filled with old German fountain pens: An exiting project! PART 2 of 4

Read part 1 first!

http://fpgeeks.com/forum/showthread.php/11054-A-suitcase-filled-with-old-German-fountain-pens-An-exiting-project!-PART-1-of-4

This is continuation of part 1

The piston system is out of the barrel tube. The piston tube is screwed on the metal piston rod, so the 2 parts have to be disconnected. As the metal piston rod and the nut in the piston tube are heavily oxidised this is not easy. The metal is a very brittle zinc alloy called ZAMAK (http://nl.wikipedia.org/wiki/Zamak) that easily breaks. This is the most critical part of the disassembly. If the Zamak nut in the piston tube can still move freely from the Zamak rod, the parts can easily be taken apart.

But when the 2 ZAMAK parts are oxidised together (metal oxide diffusion), there's a big chance it breaks as you can see here. End of story for this piston part!

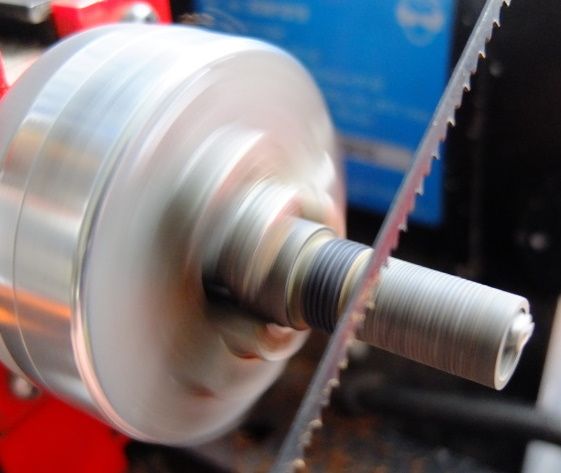

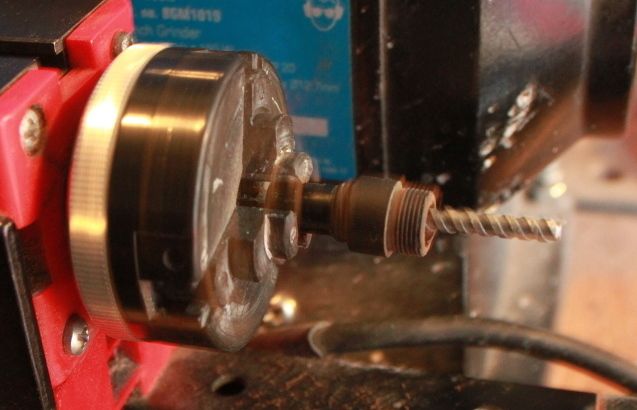

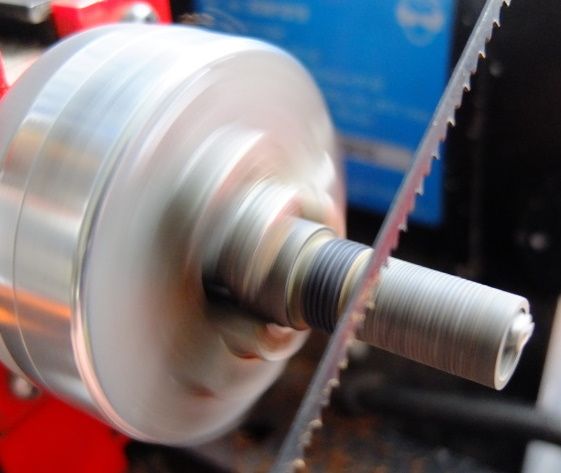

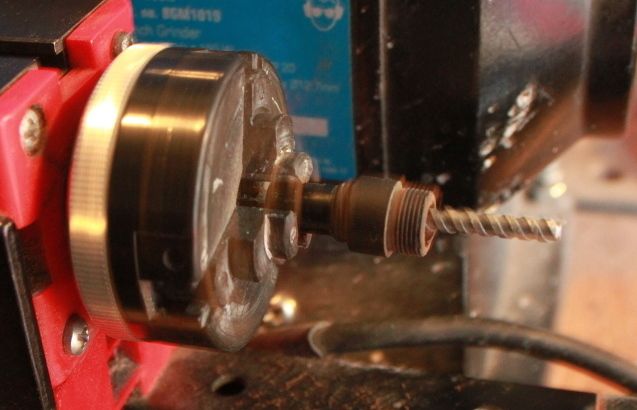

When the parts do come apart it looks like this. To be able to clean and re-polish the metal piston rod, a small modification is needed. The wide tube that receives the narrower piston tube has to be removed, in order to reach the metal parts. This is no problem as the piston is also held in place by the cork in the barrel.

When the receiver tube is removed, the metal piston screw comes in sight and in reach, so it can be polished. The oxide layer is removed and the rod can be screwed in and out and turn freely in the metal nut of the piston tube. Some silicone grease is applied to ensure the movement of the parts.

Here you can see some repaired piston systems. In some cases the original corks are still in a good condition. But many times they are either shrunken or even irrepairably damaged. Then it must of course be replaced by a new cork. When shrunken, some corks can be revived by gently heating them and applying some bees wax while the cork is heated. The pores of the cork will open, the bees wax impregnates the cork and it will swell to its original measure. When the cork fits snugly in the barrel it will do its work again for quite a long time. A thorough test is essential: If it still slips or even leaks it has to be replaced by a new cork.

The completely disassembled pen.

To be continued in part 3

http://fpgeeks.com/forum/showthread.php/11056-A-suitcase-filled-with-old-German-fountain-pens-An-exiting-project!-PART-3-of-4

Last edited by Lexaf; March 19th, 2015 at 12:01 PM.

-

The Following 10 Users Say Thank You to Lexaf For This Useful Post:

ashfaque (April 9th, 2015), elaineb (March 19th, 2015), farmdogfan (March 19th, 2015), Frantik (March 20th, 2015), Haefennasiel (March 21st, 2015), hsianloon (March 29th, 2015), Jeph (March 20th, 2015), john (March 29th, 2015), Kaputnik (March 19th, 2015), Neo (March 19th, 2015)

-

March 29th, 2015, 04:19 PM

#2

Junior Member

- Rep Power

- 0

Re: A suitcase filled with old German fountain pens: An exiting project! PART 2 of 4

Re: A suitcase filled with old German fountain pens: An exiting project! PART 2 of 4

Thank you for the post. It's great to get a bit of an insight on what goes into restoring pens. Looking forward to what happens next

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks